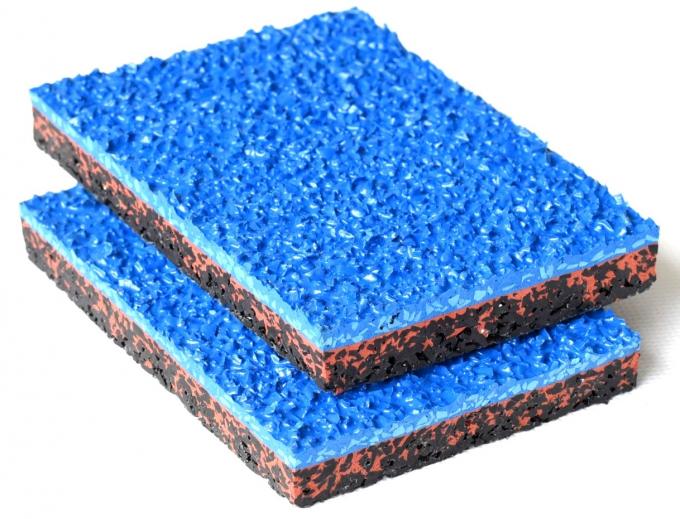

Stadium Sandwich System Running Track EPDM Rubber Flooring Surface

Product Details:

| Place of Origin: | Guangzhou, China |

| Brand Name: | SDONG |

| Certification: | IAAF / ITF / ISO9001:2008/ ISO14001/ ISO18001/ SGS |

| Model Number: | SB02-603 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 500 sq.m |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Pack in barrel / carton/ fiber bag |

| Delivery Time: | 10 days after your deposit |

| Payment Terms: | L/C, T/T, Moneygram, Paypal, Western Union |

| Supply Ability: | 10000 sq.m per Month |

|

Detail Information |

|||

| Product Name: | Sandwich System Running Track | Thickness: | 7mm-13mm, Or Customized |

|---|---|---|---|

| Colour: | Red,Blue,Grey | Service Life: | 7-10 Years |

| Feature: | Good Elasticity, Water Resistance | Main Components: | Primer, SBR, EPDM Granules, PU Binder |

| Weather: | All Weather Used | Foundation: | Cement Or Pitch |

| Type: | Spray Cost ,sandwich Cost , Mixed Cost | Delivery Times: | 10-15 Days |

| Transport Package: | Barrels And Pallets | Pattern: | Sand |

| Packing: | 25kg/bag ,40bags/pallet Or 60 Bags/pallet | Granule Size: | 0.5-2mm,1-2mm, 1-3mm |

| High Light: | Stadium Sandwich System Running Track,7mm Thickness Sandwich System Running Track,EPDM Sandwich System Running Track |

||

Product Description

EPDM Rubber Flooring Surface Sandwich System Stadium Running Track

Description

The pure plastic track has a flat and dense structure, mainly composed of two-component polyurethane material, which is made of polyurethane glue. Polyurethane slurry is integrated with antioxidant, UV-resistant agent and pigment. Combined with kinematics and material science, it can fully meet the professional requirements of athletes for the track when it is used in professional fields.

- Environmental-friendly,non-toxin,non-pollution and recyclable

- Free of heavy metal,no harmful substance

- All weather use;indoor&outdoor use

- Nice performance for aging;electriacl insulation,corrision and impact-resistant

- Convenient to install and easy to maintain

- Long service time:over 10 years

- Structure: 2mm thickness special thick liquid(Self-knot Pattern) top layer plus 11mm thickness PU glue mix SBR rubber particle on the Bottom

Main components:

1.Primer

2.SBR

3.PU binder

4.Spray coat

5.EPDM Granules

6.Line painting

Features of spray coat running track:

1.soft, comfortable and cost-effective surface

2.Good elasticity, Water resistance, Slip resistance, Spike resistance

3.Easy to install and repair

4.Excellent UV resistance

5.Asphalt or Concrete sub-base

6.Save and anti-skidding ect.

Granule packing:

25kg/bag ,40bags/pallet or 60 bags/pallet

20 tons/20' GP container or 28 tons/40' GP container

PU packing:

20kg/bucket, 18ton/20ft container

200kg/drum, 16ton/20ft container.

Applications

Applicable to all types of schools at all levels and professional stadium, athletics track, semicircle area, auxiliary area, fitness paths, indoor stadium training track, playground surfacing roads, indoor and outdoor track.

Specifications

| Full PUR Running Track Material Physical Performance Test Report | ||||

| Test items | Limited Value | Result | judgement | |

| Shock absorption % | (0±2)ºC | (35-50) Athletic Running Track |

40.2 | Conformity |

| (23±2)ºC | 42.7 | Conformity | ||

| (50±2)ºC | 43.5 | Conformity | ||

| Vertical deformation (mm) | 0.6-3.0 | 2.5 | Conformity | |

| Anti-skid value (BPN 20ºC) | ≥47(wet condition) | 52.4 | Conformity | |

| Tensile Strength (MPa) | ≥0.5 | 0.84 | Conformity | |

| Elongation at break (%) | ≥40 | 170 | Conformity | |

| Fire Resistance (Grade) | 1 (Burning spot diameter≤50mm) |

1 (Burning spot diameter≤34mm) |

Conformity | |

Plastic track features

1, all-weather: Any season and temperature, are at high quality available, can be used immediately after the rain, greatly improving site utilization.

2, moderate flexibility: flexibility and rebound moderately can reduce physical exertion, improve scores.

3, the impact absorption: moderate foot shock absorption to reduce sports injuries, long-term exercise and competition are appropriate.

4, impact resistance: a tough elastic layer and buffer layer, can absorb strong impact, the surface is not damaged.

5, weather resistance: not because of ultraviolet radiation, ozone, acid rain, pollution and bleaching, powder or soften, long-term bright colors.

6, wear: wear resistance of less than 2.5%, to meet the needs of the high frequency of use.

7, compression resistance: the weight of track and field equipment, restore flexibility.

8, anti-nail resistance: In the largest stress meters most frequently used starting point, it will not be spikes or starting frame damage.

9, flatness: Use self-leveling construction materials, flat surface, in line with the venue of the flatness of the high demand.

10, adhesive: Special construction treatment, adhesive power, can suppress the rising water, no blistering, peeling and so on.

11, security: to prevent fall injury occurred.

12, economy: easy maintenance, saving management costs.

13, Artistry: The special high elastic particles, surface color soft; granular surface, to prevent the dazzling light reflection; be more than color matching.

Running Track

FAQ:

Q1: Are you a factory or a trade company?

A1: We are an industry and trade company.Welcome to China factory inspection.

Q2: What is thickness for the IAAF Running Track?

A2: The International Standard thickness is 13mm. Other sizes are available as your request.

Q3: Can we get installation support if we have no own constructors?

A3: We can send salesmen and technical support to your country to assist the installation.

Q4: Are your running track materials safety?

A4: Yes, our materials are safe. Environmentally friendly and recyclable.

Q5: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

Q6: What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages

before you pay the balance.

Q7:What is the Production time?

A:It is about 10-15days.

Q8:What are the options for the base construction of a running track.?

A:The ground is based on asphalt or concrete.

Q9:What is the life Span for Running track?

A:The life span is about 10-15years.

Q10:I am Interested in Synthetic track surface,what is the best choice?

A: We have 4 system:Spray coat,Sandwich,Full pour and Prefabricate system.

Spray coating:Price competitive , permeable and surface paint by machine, more suitable for school or practice project

Sandwich system: EPDM broad be handwork,is professional than spray coat, enjoying great popular in the world market.

Full pour System: Best quality, Bottom layer is PU with less sbr granules mix. Suitable for professional games and international school.

Prefabricated system: Is package by roll, Specification is 1.22*15m/20M, Strict request with base ground flat level. Professional for stadium international games. Like Olympic games.