Colorful Soft EPDM Granules SBR Rubber Safety Tiles Shock Proof

Product Details:

| Place of Origin: | Guangzhou, China |

| Brand Name: | SDONG |

| Certification: | IAAF / ITF / ISO9001:2008/ ISO14001/ ISO18001/ SGS |

| Model Number: | SB03-703 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 500 sq.m |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Pack in barrel / carton/ fiber bag |

| Delivery Time: | 10 days after your deposit |

| Payment Terms: | L/C, T/T, Moneygram, Paypal, Western Union |

| Supply Ability: | 10000 sq.m per Month |

|

Detail Information |

|||

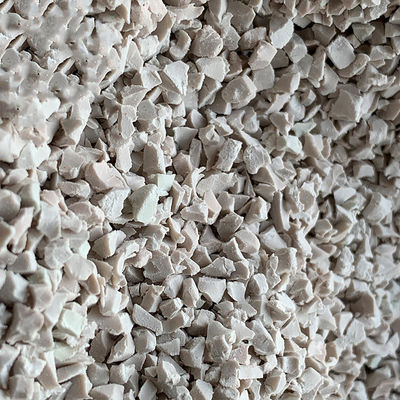

| Item: | Outdoor EPDM Rubber Flooring Mat | Texture: | EPDM Granules |

|---|---|---|---|

| Measure: | 0.5-1.5mm,1-2mm, 1-3mm,2-3mm Or Customized | Acid Resistance: | Excellent |

| UV Resistance: | Excellent | Warranty: | Serve More Than 10 Years |

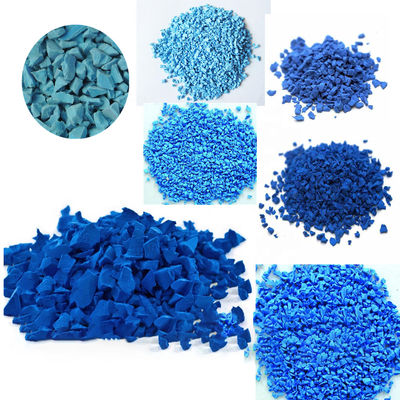

| Colour: | Red, Green,yellow,blue,black,grey Or Customized | Including Rubber Percentage: | 8%-33% |

| Feature: | High Elasticity, Shock-proof, And Shock Absorption | Sample: | Free For Sample,freight Self-pay |

| Base: | Cement Or Asphalt | OEM/ODM: | Available |

| Specification: | 25kg/bag; 40bags/pallet | Usage: | Athletic Flooring, Multi-sports Areas Tennis, Pool Surroundings, Walkways Playground Areas |

| High Light: | SBR Rubber Safety Tiles,Soft EPDM Rubber Safety Tiles,ODM Rubber Safety Tiles |

||

Product Description

Colorful Soft EPDM Rubber Granules Shock-Proof SBR Rubber Safety Tiles

Instructions:

Step-1: Clean the ground, remove the dust;

Step-2: Brush the binder onto the ground, to makethe ground connect with the granules tightly;

Step-3: Weight the Granules and binder according tothe ratio (1:5.5=binder: granules), mixed them totallyby hand tools or by machine:

Step-4: Put the mixed granules onto the ground, flatthe granules by hand tool or by machine

Step-5: Use straight wood, to help the workers installone color in the line, one color finished, workers, canstart the other colors;

Step-6: Finished. About 12 hours later, it will bedried, and people can step or walk on it.

Feature:

• Best raw materials used

• Excellent wear resistance

• Non-toxic and Environment Friendly

• Long period to use

• High Flexibility and Durability

• Color consistency

• UV resistant properties

• Easy installation and maintain

• High weather stability

• Apply widely

• Full range of colour available

EPDM rubber is a type of synthetic rubber that can have a wide range of applications.

1. Resistance to color changes.

2. Non-affected by the weather.

3. It has high elasticity, shock-proof, and shock absorption.

4. Good abrasive resistance and durability.

5. Save and anti-skidding.

6. Various colors. Can be made according to customer requirements.

Advantages of EPDM rubber floor:

- Anti-aging: It is not affected by ultraviolet light, ozone, wind and rain, and it is faded and powdered. It can maintain bright colors for a long time and has a long life.

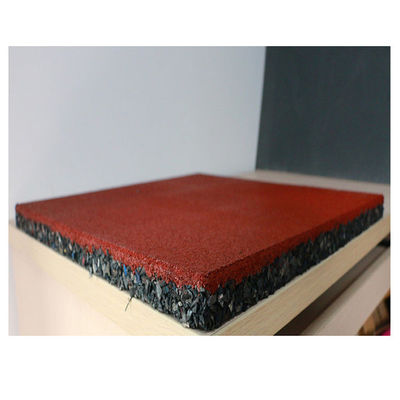

- Impact resistance: It has a strong elastic layer and a buffer layer, which can absorb strong impact.

- Diverse colors: colorful, can be assembled in a variety of colors.

- Foundation conditions: The basic requirements are simple, even poor foundations can be paved and the adhesion is good.

Our Competitive Advantage?

What's our competitive advantage different from similar manufacturers of recycled rubber products?Details below:

• We have integrated our experience and expertise to provide best quality EPDM granules to our clients. Known for its resistance to wear and tear, the offered product is widely regarded among our valued patrons. Driven by an intense desire to serve the satisfaction of our clients, we further offer customization as per the specification briefed by the clients themselves.

• As the 16th Guangzhou Asian Games venues nominated materials supplier,we stands out as the only manufacturer producing its own tire crumb, EPDM granules.

• We have 16 years experiences specilize in EPDM granules and this allows our company to offer an unrivaled variety of products for use in school playground,safety place and athletic running track.

• With full control over the production of materials used to make its products, we can offer quality control and reliability that no competitor can match.

Installation steps:

1. Apply a layer of glue to the concrete field base, and mix the glue and particle in a ratio of 1:5.5 with hands or a mixer.

2. Spread the mixed material evenly on the concrete field base, and compact and flatten them with a pressure plate. The thickness you can control by your self, generally, the thickness of 1 mm square meter will cost 1.1 kg of EPDM particles.

| Texture | SBR Particles,EPDM Granules |

| Thickness | 8-15 mm or customized |

| Color | Red,Green,Blue,White or Customized |

| Size | 0.5-1.5mm,1-2mm, 1-3mm,2-3mm or Customized |

| Color stability | Excellent |

| Granule Content | 14%, 20%, 22%, 25%, 35%, 40% etc. |

| Overseas Installation | available |

Rubber Playground Mats Application

EPDM particles are widely used in the surface layer of various sports venues (such as sports track, football field, tennis court, basketball court, volleyball court etc, ) , schools, kindergartens, amusement parks, parks, sidewalks, fitness trails, all kinds of stadium safety mats, gyms and other sports venues ground paving.

FAQ:

Q:What is the Production time?

A:It is about 20-25days.

Q:What are the options for the base construction of a running track.?

A:The ground is based on asphalt or concrete.

Q:What is the life Span for Running track?

A:The life span is about 10-15years.

Q : Is it the EPDM granules made of new EPDM rubber or Recycled rubber?

A : All of our products are made of New EPDM rubber, not recycled rubber.

Q : How many EPDM granules will be needed for 1 Square meter?

A : 3.5kg EPDM granule for 1 square meter

Q:Can we get installation support if we have no own constructors?

A: We can send salesmen and technical support to your country to assist the installation.

Q: Are your running track materials safety?

A: Yes, our materials are safe. Environmentally friendly and recyclable.

Q: What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages before you pay the balance.

Q:What is the Production time?

A:It is about 10-15days.

Q:What kind of products do you have?

A: Our product about Running track, Artificial grass field, Interlocking sport floor tiles, EPDMSBR system running track, Sport flooring, material, tools and so on.

Q: Are you a manufacturer?

A: Yes, we are a professional production factory in this field since 2004.

Q: How long is your delivery time?

A: Generally it is 3-5days if the goods are in stock. or it is 5-10days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: Is the EPDM granules made of new EPDM rubber or Recycled rubber?

A: All of our products are made of New EPDM rubber, not recycled rubber.

A: Yes, according to the detailed drawings you provide.

Q: How to pay?

A: Via T/T payment, L/C, MoneyGram, Trade Assurance, and other payments. About the payment details please feel free to contact us. Thank you!