Stadium Eco Sports Flooring Track Waterproof Sport Surfaces

Product Details:

| Place of Origin: | Guangzhou, China |

| Brand Name: | SDONG |

| Certification: | IAAF / ITF / ISO9001:2008/ ISO14001/ ISO18001/ SGS |

| Model Number: | SB02-601 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 500 sq.m |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Pack in barrel / carton/ fiber bag |

| Delivery Time: | 10 days after your deposit |

| Payment Terms: | L/C, T/T, Moneygram, Paypal, Western Union |

| Supply Ability: | 10000 sq.m per Month |

|

Detail Information |

|||

| Product Name: | Eco Sports Flooring Track | Thickness: | 9-15mm (recommend 13mm) |

|---|---|---|---|

| Application: | Multi-use,Playgound/ Sports Court | Colour: | Red, Blue And Customized |

| Service Life: | 6-10 Years | Feature: | Eco-friendly, Non-poisonous, Harmless And Odorless |

| Material: | PU Glue, SBR Granule, EPDM Granule | Weather: | All Weather Used |

| Base: | Cement Concrete Or Bituminous Concrete | Usage: | School, Communities, Stadium, Training Center |

| Sample: | Free | Track Type: | Sandwich System, Spray Coating System, Prefabricated System |

| High Light: | Stadium Eco Sports Flooring,Waterproof Eco Sports Flooring |

||

Product Description

IAAF Approved Stadium Eco Sports Flooring Track Waterproof Sport Surfaces

Description

Running Track Athletic Track

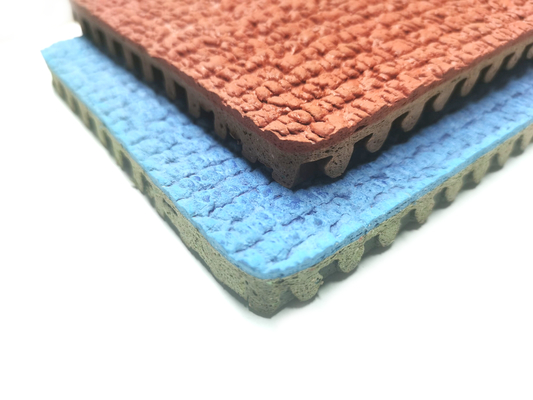

The base layer consists of Black Styrene Butadiene Rubber(SBR) granules,bound together with a specially formulated, 100% s olids MDI based single component polyurethane,at a thickness of 10mm(3/8inch).

The top layer consists of a specially formulated, colored polyurethane into Ethylene Propylene Dience Monomer(EPDM) which granules have been embedded before curing for a thickness of 3mm(1/8inch).

| Name | Prefabricated System Running Track |

| Base Requirement | Cement Concrete or Bituminous Concrete |

| Thickness | 9-13mm |

| Suitable Scope | EDPM,PU Binder |

Advantage:

- High Quality

Using high quality material and establishing a strict quality control System, assigning specific persons in charge of each part of production,from raw material purchase to installation service.

- Installation Service

With 20 years of installation experience our installation team are capable of lAAF marking with certificate. Engineers can be dispatched to any country for on-site installation guidance.

- Fast Dispatch

Most of the products are in Fast Dispatch stock. Quantity below 1000sqm can be delivered within 7 days.

- Small Order Accepted

Low MOQ accepted. 200 SQM are available.

Specifications

|

Product |

PU track |

||

|

Thickness |

13 mm or customized |

||

|

Force Reduction |

41 |

||

|

Tensile Strength |

1.56 |

||

|

Elongation at break |

92 |

||

|

Modified Vert. Deform. |

1.9 mm @ 23°C [75°F] |

||

|

Friction |

0.64/48 |

||

|

Material |

EPDM, SBR, Reclaimed Rubber, ETC. |

||

|

Features |

Environmental-friendly, UV-resistance, 5--10 years service time |

||

|

Market |

North America, Southeast Asia, Western Europe, Domestic Market |

||

|

Application |

Outdoor Rubber Track, Playground Sports Flooring,etc. |

||

|

More Test Data |

|||

|

Test Item |

Reference |

Standard Data |

Test Result |

|

Tensile |

IAAF |

≥0.5 |

1.56 |

|

Elongation at Break |

IAAF |

≥40 |

92 |

|

Force Reduction |

IAAF |

35-50 |

41 |

|

Vertical Deformation |

IAAF |

0.6-2.5 |

2.3 |

|

Skid Resistance |

IAAF |

≥47 |

57 |

|

Hardness Shore A |

GB/T 14833-2011 |

45-60° |

45-55° |

|

Fire Rating |

GB/T 14833-2011 |

I Degree |

I Degree |

|

Color Stability |

|

|

Good |

|

Chemical Resistance |

|

|

Good |

Running Track Photos

FAQ:

Q1: Are you a factory or a trade company?

A1: We are an industry and trade company.Welcome to China factory inspection.

Q2: What is thickness for the IAAF Running Track?

A2: The International Standard thickness is 13mm. Other sizes are available as your request.

Q3: Can we get installation support if we have no own constructors?

A3: We can send salesmen and technical support to your country to assist the installation.

Q4: Are your running track materials safety?

A4: Yes, our materials are safe. Environmentally friendly and recyclable.

Q5: How do you make our business long-term and good relationship?

A:1. We keep good quality and competitive price to ensure our customers benefit ;

2. We respect every customer as our friend and we sincerely do business and make friends with them,

no matter where they come from.

Q6: What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We'll show you the photos of the products and packages

before you pay the balance.

Q:What is the Production time?

A:15-25days.

Q:What are the options for the base construction of a running track?

A:Based on asphalt or concrete.

Q:What is the life Span for Running track?

A:10-15years.

Q:How many system of Synthetic track surface,what is the best choice?

A: 4 system:Spray coat,Sandwich,Full pour and Prefabricate system.

Spray coating:Price competitive , permeable and surface paint by machine, more suitable for school or practice project

Sandwich sytem: EPDM broad be handwork,is professional than spray coat,most pouplar in the world market.

Full pour System: Best quality, bottom layer is PU with less sbr granules mix. Suitable for professional games and international school.